Water inflow limitation/isolation of water-bearing intervals in oil & gas wells applying polymers and magnetic substances is performed to isolate/limit water inflow into the producing well.

The technology is based on creating and placing an isolation screen in required intervals of the productive horizon by magnetic field. Unlike other methods of isolation and water inflow limitation, the proposed technology provides the possibility of selective interval treatment.

This technology is also practicable to ensure the cement integrity when the use of a packer proves to be ineffective. Pumping down the cement slurry containing polymers and magnetic substances increases the strength of the isolation screen in the required intervals.

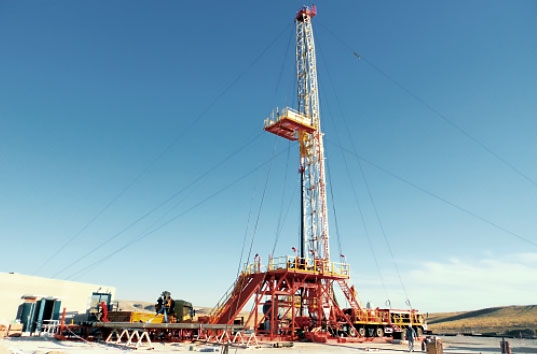

This technology is implemented using the standard field equipment by running a special magnetic field generator into the well. Technology is highly efficient due to the use of standard equipment and low chemicals consumption.

In order to create watertight screens in the productive reservoir, cement slurry with added

magnetic substances are used. Under the influence of magnetic fields generated inside the wells strong isolation structures are formed in the reservoir that shut off water bearing

intervals/zones. This technology is successfully applied in the oil fields of Turkmenistan.